The Difference Between Design Drawings and Shop Drawings

In the development and production industries, drawings are critical in transforming thoughts into fact. Two of the most generally used drawings are layout drawings and as-built drawings. While they may appear similar before everything glance, they serve distinctive functions and are used at different degrees of a task. Understanding the variations between these styles of drawings is critical for architects, engineers, contractors, and fabricators to ensure clean mission execution.

What Are Design Drawings?

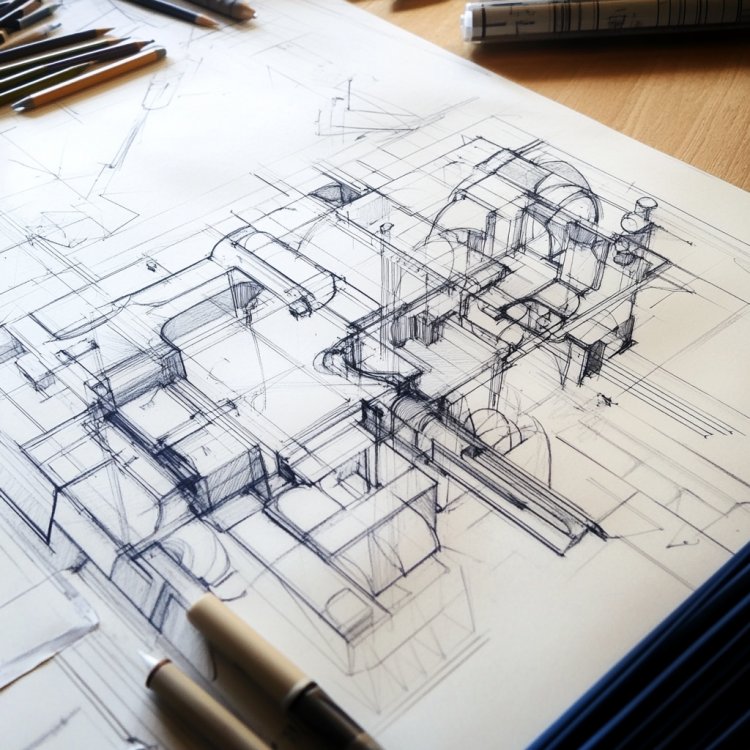

Design drawings are conceptual plans created all through the early stages of a venture. These drawings focus on the general appearance, function, and format of a structure or product. They offer a visible representation of the way the final production or product will appear, supporting clients and stakeholders in understanding the layout purpose.

These drawings are normally created by using architects or engineers and function as a guide for the task's development. They include information about dimensions, materials, and structural elements; however, do no longer offer the level of specificity required for fabrication or meetings. Since layout drawings are not meant for direct production or construction, they require extra detailing before real implementation.

During this level, professionals operating on shop drawing offerings may also discuss with design drawings to expand more specified and fabrication-ready plans. Design drawings act as a basis, supporting drafters to refine technical details using 2D drafting services to create particular illustrations needed for execution.

What Are Shop Drawings?

Shop drawings, then again, are relatively detailed technical drawings used for the manufacturing, meeting, or construction of precise additives. These drawings are advanced based on layout drawings but encompass additional specs vital for fabrication.

Unlike layout drawings, which focus on aesthetics and general venture vision, shop drawings provide particular measurements, material specs, and detailed instructions for how every element needs to be manufactured and set up. They are generally used in numerous industries, together with production, metallic fabrication, millwork, and mechanical systems.

Companies presenting shop drawing offerings specialize in specialized, detailed technical illustrations, making sure that each additive meets challenge specifications. By leveraging 2D drafting offerings, professionals can expand correct and dimensionally accurate shop drawings that streamline fabrication and meeting methods.

Key Differences Between Design Drawings and Shop Drawings

1. Purpose and Function

Design drawings are cognizant of conceptualizing and visualizing a mission, while shop in mind that design drawings are created for actual construction or production. Design drawings assist stakeholders in understanding the venture’s vision, while shop drawings provide step-by-step guidance for fabrication and setup.

A project usually starts with layout drawings and later transitions into final drawings, in which specialists in the deep draw services refine and decorate information for creation. The use of 2D drafting services saves drawings, and guarantees accuracy and compliance with challenge necessities.

2. Level of Detail

Design drawings provide a large amount of a challenge, frequently lacking precise specs for fabrication. These drawings may additionally consist of general dimensions, format plans, and inventive renderings; however, they do not, incorporate the technical information required for direct implementation.

Shop drawings, however, are some distance more unique. They encompass precise measurements, cloth specs, connection info, and installation tips. The precision of shop drawings allows fabricators and contractors to execute projects with minimum errors. Experts in save drawing services use superior 2D drafting services to ensure accuracy and consistency in those unique drawings.

3. Who Creates Them?

Design drawings are generally created by architects, engineers, or designers. These experts recognize the aesthetic and useful factors, making sure that the overall idea aligns with client necessities and regulatory standards.

Shop drawings, on the other hand, are created via specialized drafters, contractors, or producers. Companies providing shop drawing offerings take design drawings and convert them into fabrication-prepared documents with the use of 2D drafting services. These specialists work closely with producers to make certain that each component suits collectively efficaciously.

4. Role inside the Project Timeline

Design drawings are advanced at the start of an assignment and function as a manual for planning, approval, and coordination. They assist clients in visualizing the project and provide routes for engineers and contractors.

Shop drawings are created later in the undertaking, as soon as the design has been finalized. These drawings are crucial for procurement, fabrication, and setup, ensuring that each thing meets the intended specifications. By the use of shop drawing services, groups can bridge the gap between conceptual and physical construction, whilst 2D drafting services help refine each element.

5. Use in Construction and Fabrication

Design drawings provide an average framework for a mission, however they do no l,onger include the precise details wanted for manufacturing or setup. Fabricators, steelworkers, and creation teams rely upon shop drawings to execute the actual work.

For instance, a layout drawing of a staircase may also show its form, dimensions, and materials. However, a shop drawing will encompass details along with the precise dimensions of every step, the kind of bolts required, welding specifications, and fabric thicknesses. This level of element is essential for making sure that every factor suits flawlessly. Professionals specializing in shop drawing services develop these technical documents with the assistance of 2D drafting services to make sure accuracy.

Why Both Types of Drawings Are Important

Both design drawings and shop drawings play important roles in the creation and manufacturing industries. While design drawings assist in establishing the task's imaginative and prescient and secure approvals, shop drawings offer the essential technical info to deliver that imaginative and prescient to life.

By using professional shop drawing services, groups can ensure that their tasks transition easily from design to execution. Additionally, leveraging 2D drafting services enables enhanced errors, and optimization, in the long run leading to fee savings and better efficiency.

The Role of Technology in Design and Shop Drawings

Advancements in CAD software and digital drafting techniques have made it easier to create both layouts and save drawings with excessive precision. Many firms now depend upon 2D drafting services to increase clean and precise technical illustrations. These offerings offer correct scaling, regular formatting, and clean modifications, which might be essential for both conceptual and fabrication drawings.

Companies offering shop drawing services utilize modern-day drafting gear to supply comprehensive drawings that meet enterprise requirements. The potential to convert layout concepts into specific fabrication-prepared plans guarantees that creation and production approaches continue without errors or delays.

Conclusion

Understanding the variations between layout drawings and shop drawings is vital for a hit mission execution. While designing drawings attention on conceptualizing a mission, shop drawings offer the detailed technical specifications needed for fabrication and set up.

Businesses that put money into professional shop drawing services advantage of accurate, nicely-based documentation that improves performance and decreases errors. Additionally, utilizing 2D drafting offerings enhances clarity and precision in all technical drawings, ensuring seamless collaboration between architects, engineers, and fabricators.

By leveraging both layout and shop drawings successfully, organizations can attain better task effects, reduce transformation, and make sure splendid cons of sequences. Whether you're working on a construction challenge, a manufacturing method, or an engineering undertaking, having the right drawings at every level is key to success.

What's Your Reaction?

.jpg)