Electrically Conductive Epoxy Adhesive Market Outlook: Growth, Share, Value, Size, and Insights

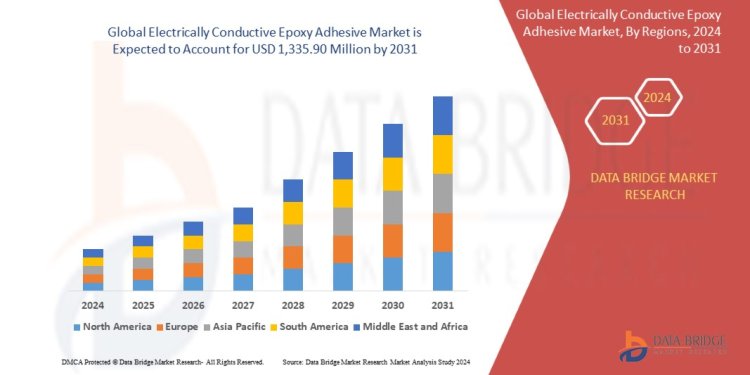

Data Bridge Market Research analyses that the electrically conductive epoxy adhesive market which was USD 774.4 million in 2023, will reach USD 1,335.90 million by 2031, and is expected to undergo a CAGR of 7.1% during the forecast period.

Introduction to Electrically Conductive Epoxy Adhesives

Electrically conductive epoxy adhesives are specialized polymer formulations that combine the bonding strength of epoxies with electrical conductivity. These advanced materials are revolutionizing electronics manufacturing by providing reliable electrical connections without traditional soldering.

The global electrically conductive epoxy adhesive market is experiencing robust growth, driven by the electronics industry's need for smaller, lighter, and more reliable components. These adhesives offer unique advantages over conventional solders, including better mechanical strength, corrosion resistance, and compatibility with heat-sensitive materials.

Composition and Working Mechanism

Key Components

Epoxy Resin Matrix

Provides structural integrity and adhesion properties to the formulation.

Conductive Fillers

-

Silver: Most common filler offering highest conductivity

-

Copper: Cost-effective alternative with oxidation challenges

-

Carbon/Nickel: Used for specific applications requiring moderate conductivity

Curing Agents and Additives

Determine curing characteristics and enhance specific properties like thermal stability.

Types of Electrically Conductive Epoxies

Isotropic Conductive Adhesives (ICAs)

Conduct electricity equally in all directions, ideal for general electronic assembly.

Anisotropic Conductive Adhesives (ACAs)

Conduct only in the Z-axis, perfect for fine-pitch applications like display interconnects.

Key Applications Across Industries

Electronics and Semiconductor Industry

-

PCB Assembly: Component attachment and repair

-

Die Attach: Critical for semiconductor packaging

-

Flexible Circuits: Enabling bendable electronics

Automotive Electronics

-

EV Battery Packs: Cell-to-cell connections

-

ADAS Sensors: Reliable connections in harsh environments

Aerospace and Defense

-

Avionics: Vibration-resistant connections

-

EMI Shielding: Protecting sensitive equipment

Market Growth Drivers

The electrically conductive epoxy adhesive industry is propelled by:

-

Electronics Miniaturization: Need for smaller, more reliable interconnects

-

EV Revolution: Growing battery and power electronics applications

-

Environmental Regulations: Phasing out of lead-based solders

-

5G Expansion: Demand for high-frequency compatible materials

Latest Technological Advancements

Innovations shaping the market include:

-

Nano-filler Technology: Enhanced conductivity at lower filler loading

-

Low-Temperature Cures: For heat-sensitive components

-

Dual-Cure Systems: Combining UV and thermal curing

-

Thermally Conductive Formulations: Addressing heat dissipation challenges

Challenges and Limitations

Key hurdles facing adoption:

-

Cost Premium: Silver-filled formulations can be expensive

-

Conductivity Limits: Still below traditional solders

-

Process Sensitivity: Requires precise application techniques

-

Long-Term Reliability: Concerns about conductivity degradation

Regional Market Analysis

-

Asia-Pacific (45% market share): China, Japan, and South Korea lead in electronics manufacturing

-

North America (30%): Strong in aerospace and advanced electronics

-

Europe (20%): Driven by automotive and environmental regulations

-

RoW (5%): Emerging opportunities in industrial automation

Competitive Landscape

Major players include:

-

Henkel AG & Co. KGaA

-

3M Company

-

Parker Hannifin Corp (Lord Corporation)

-

Master Bond Inc.

-

H.B. Fuller Company

Recent developments feature:

-

New silver-alternative formulations

-

Expansion in Asian production facilities

-

Strategic partnerships with EV manufacturers

Future Outlook and Growth Projections

The market is projected to grow at 8.5% CAGR (2024-2030), reaching $1.2 billion by 2028. Future opportunities lie in:

-

Quantum Computing: Ultra-precise interconnection needs

-

Flexible Hybrid Electronics: New form factors

-

Sustainable Formulations: Bio-based resins and recycled fillers

Conclusion

Electrically conductive epoxy adhesives are becoming indispensable in modern electronics manufacturing, offering unique solutions where traditional soldering falls short. While challenges remain in cost and performance, continuous innovation is expanding their applications across industries. As technology advances toward more compact and sophisticated electronic systems, the electrically conductive epoxy adhesive market is poised for sustained growth, playing a critical role in powering the devices of tomorrow.

Get More Details : - https://www.databridgemarketresearch.com/reports/global-electrically-conductive-epoxy-adhesive-market

Get More Reports :

https://www.databridgemarketresearch.com/reports/global-blockchain-in-agriculture-market

https://www.databridgemarketresearch.com/reports/global-mega-solar-power-plant-market

https://www.databridgemarketresearch.com/reports/global-athletic-footwear-market

What's Your Reaction?

.jpg)